Stronger Bonds, Better Business: Why Adhesion Matters in UV Printing

Durable prints don’t just happen. They depend on a strong bond between ink and substrate. In UV printing, adhesion is the difference between a vibrant product you can sell and one that chips, peels, or fails in the field. While not every job requires extra help, there are times when an adhesion promoter can make or break the final result.

What Is an Adhesion Promoter?

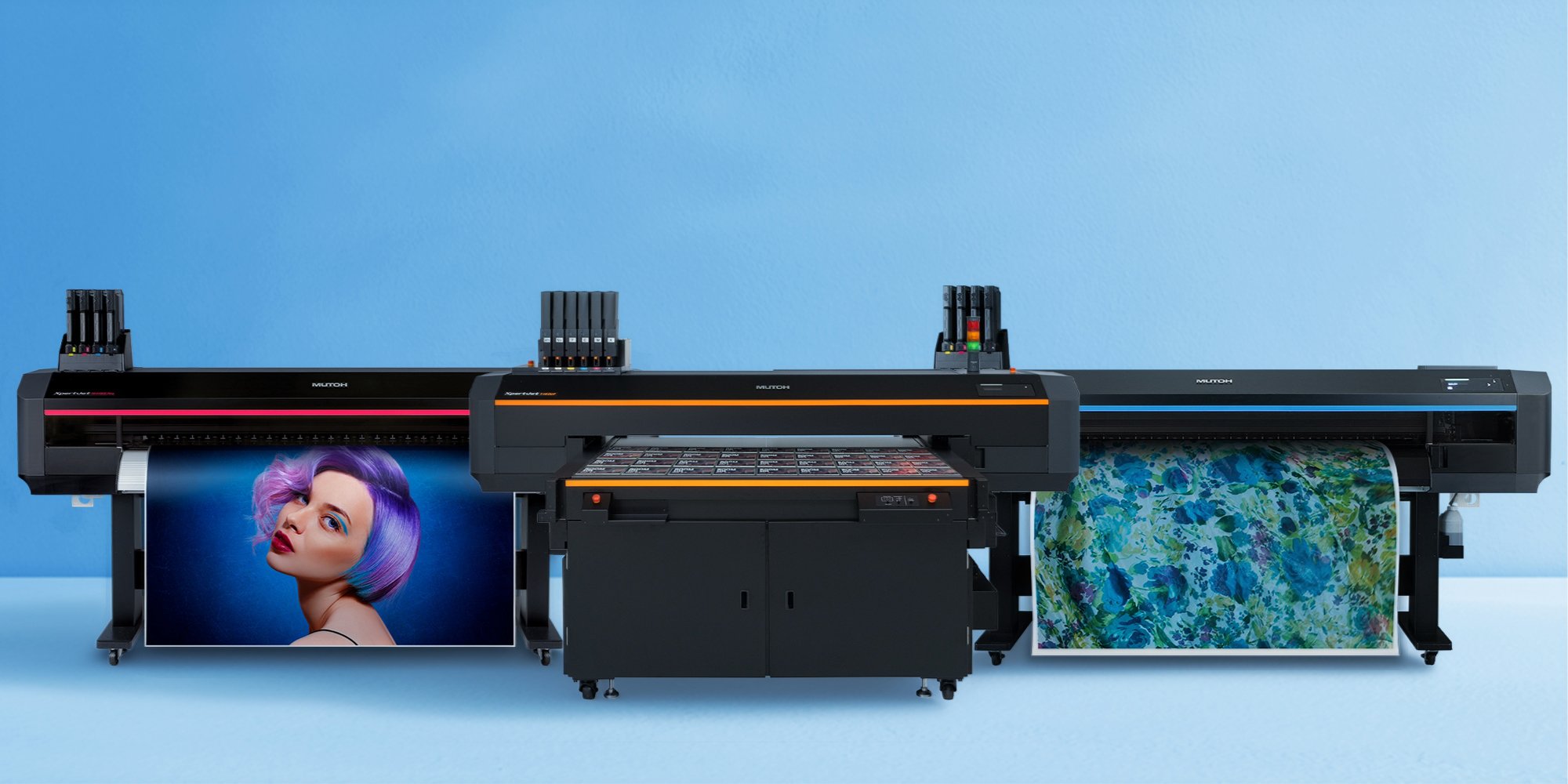

At MUTOH, we are proud to support our customers with more than the printer – we provide training opportunities, an educational kit on specific printers, and tips to help the industry move past the challenge while making money.

In the simplest terms, an adhesion promoter is a chemical product that improves the bond between UV-curable ink and the surface being printed. Some substrates naturally accept UV ink, while others resist it due to their chemistry or surface energy. Adhesion promoters bridge that gap.

Common types include:

- Liquid wipe-on coatings – applied by hand with a cloth or pad.

- Spray-on coatings – used for even application on flat or curved surfaces.

- Adhesion primers in ink – specialized formulations blended directly into UV inks.

Each method has its place depending on the material, job requirements, and production setup.

When to Use an Adhesion Promoter

Printing on Challenging Substrates

Certain materials are notoriously difficult for UV inks to adhere to. Glass, acrylic, metal, and ceramics often need help to hold ink, especially when durability is a factor. Plastics like polypropylene, polyethylene, and styrene have low surface energy, making them some of the trickiest substrates to print on without a promoter.

Printing for Outdoor & Harsh Environments

If your finished product will face rain, sunlight, chemicals, or abrasion, an adhesion promoter can help prints survive exposure. Outdoor signage, industrial labels, or equipment panels all benefit from stronger bonds.

High-Wear Prints

Objects that see frequent handling, such as drinkware, control panels, and retail signage, are prime candidates. Without extra adhesion, inks can wear off quickly in daily use.

Specialty Printing Applications

Effects like gloss layers, tactile textures, or multi-layered builds demand strong adhesion. A weak bond can cause cracking or delamination that undermines the entire design.

Why Use an Adhesion Promoter

The value of an adhesion promoter goes far beyond chemistry, it directly affects the reliability of your work and the profitability of your shop. Stronger adhesion means prints that can withstand everyday use without chipping, peeling, or scratching, so the image quality you deliver on day one is the same quality your customers see months later.

It also broadens what’s possible. Surfaces once considered “unprintable” suddenly become part of your capabilities, opening doors to projects you may have had to turn away in the past. That flexibility not only expands your portfolio, it positions your shop as a problem-solver for clients with unique requests.

And because adhesion failures often lead to costly reprints, stronger bonds also mean less waste and faster turnaround. You spend less time redoing jobs and more time moving projects out the door. The result? Happier customers, fewer warranty claims, and greater confidence in the products you create.

How to Test if You Need One

Not every job calls for an adhesion promoter. The best way to know is to test.

- Tape Test (ASTM D3359 crosshatch method): Score the ink film in a grid, apply tape, and pull. If ink comes off, adhesion is insufficient.

- Sample Prints: Run a small section on the intended substrate before committing to a full job.

Testing early saves time and helps you decide whether a promoter is required.

Application Tips & Best Practices

The difference between a strong bond and a failed print often comes down to preparation. Start by making sure the surface is clean from oils, dust, or even fingerprints can keep ink from holding. When applying the adhesion promoter, keep the coat consistent. Heavy streaks or pooling not only look unprofessional, they can weaken the bond you’re trying to create. Finally, pay attention to your environment. A clean, low-humidity workspace minimizes the risk of contamination and helps ensure the promoter performs as intended.

Common Mistakes to Avoid

Even experienced shops sometimes run into issues with adhesion promoters, and the most common problems are easy to prevent. Using the wrong promoter for a given substrate can cause the ink to fail before it ever leaves your shop. Applying too much can create hazing or discoloration, which undercuts the quality of the final print. Skipping surface prep is another trap. It’s tempting to rely on the promoter alone, but without a clean foundation, adhesion will always be compromised. And before running a full job, always confirm compatibility between your promoter and ink set. A few minutes of testing can save hours of rework.

Stronger Prints, Happier Customers

Adhesion promoters aren’t needed on every job, but when they are, they make the difference between a print that fails and one that lasts. By understanding the substrates, environments, and finishes that benefit most, your shop can deliver durable, reliable results across more applications.

In UV printing, adhesion isn’t just about ink sticking to a surface, it’s about producing work your customers can trust. With the right adhesion promoter and best practices, you’ll expand what you can offer and reduce the risks of costly reprints. Learn more by requesting samples and see the Print With Precision difference.